active rfid tool tracking RFID asset tracking involves using radio frequency identification tags and readers to track and manage assets efficiently. This technology improves accuracy, enhances efficiency and supply chain management, and provides accurate data for better asset management. Zebra ID 카드 프린터는 결제용 카드부터 직원 ID 배지와 운전면허증까지 모든 .

0 · rfid tool tracking software

1 · rfid table tracker

2 · rfid position tracking

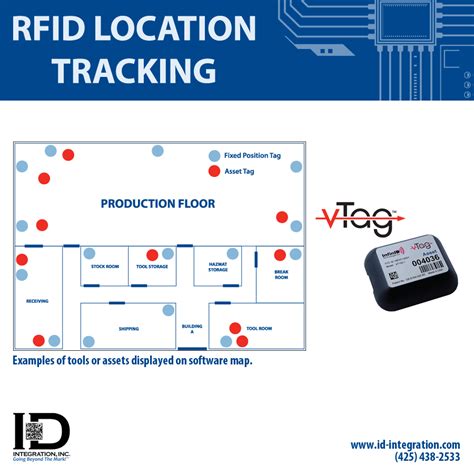

3 · rfid location tracking system

4 · rfid location tracking

5 · rfid inventory tracking

6 · rfid equipment tracking

7 · can rfid track location

$21.17

rfid tool tracking software

gemalto pci express compact smart card reader

rfid table tracker

RFID tool tracking is a powerful solution for any business looking to get better visibility into tool use and location, lengthen the life cycle of tools, and meet regulatory standards. Active, passive, or semi-passive RFID tags are all . RFID tool tracking is a powerful solution for any business looking to get better visibility into tool use and location, lengthen the life cycle of tools, and meet regulatory standards. Active, passive, or semi-passive RFID tags are all suitable solutions.This type of tracking system uses both active RFID tags, which have an internal power source, and passive RFID tags, which have no power source. Employees simply use RFID readers to scan the tags, accessing information about each tagged asset. .

RFID-based tool tracking provides an auditable record of tool usage, calibration, and maintenance, facilitating compliance with industry regulations and standards. RFID asset tracking involves using radio frequency identification tags and readers to track and manage assets efficiently. This technology improves accuracy, enhances efficiency and supply chain management, and provides accurate data for better asset management. By leveraging active RFID for asset tracking and management, inventory control, work-in-process tracking, quality control, and worker safety, manufacturers can gain real-time visibility, streamline processes, and make data-driven decisions.

Active RFID tags attached to tools allow managers to monitor when and where tools are issued and returned, helping to prevent loss and theft. Systems like our Tag & Track solution provide real-time visibility into tool availability, enabling . Active RFID systems (otherwise known as active RTLS) use battery-powered sensor tags that connect to various access points throughout an area (like a building) and transfer data to the cloud. Active RFID is commonly used for real-time location tracking.

gcc smart card software

Active RFID for real-time tool monitoring. Companies that require real-time tool monitoring across their entire work-place often turn to active RFID. Active RFID provides strategic advantages for tool monitoring over passive RFID tags: Superior range of up to 300 feet.RFID tool tracking systems can manage tools, including preventive maintenance, of all sizes, shapes, and materials – from small, metal surgical tools to large, metal and plastic power drills.RFID Tool Tracking - ToolHound’s reliable and scalable tool management software and equipment tracking system ensures tools and equipment are efficiently tracked and managed. RFID tool tracking is a powerful solution for any business looking to get better visibility into tool use and location, lengthen the life cycle of tools, and meet regulatory standards. Active, passive, or semi-passive RFID tags are all suitable solutions.

This type of tracking system uses both active RFID tags, which have an internal power source, and passive RFID tags, which have no power source. Employees simply use RFID readers to scan the tags, accessing information about each tagged asset. .RFID-based tool tracking provides an auditable record of tool usage, calibration, and maintenance, facilitating compliance with industry regulations and standards. RFID asset tracking involves using radio frequency identification tags and readers to track and manage assets efficiently. This technology improves accuracy, enhances efficiency and supply chain management, and provides accurate data for better asset management.

By leveraging active RFID for asset tracking and management, inventory control, work-in-process tracking, quality control, and worker safety, manufacturers can gain real-time visibility, streamline processes, and make data-driven decisions.

Active RFID tags attached to tools allow managers to monitor when and where tools are issued and returned, helping to prevent loss and theft. Systems like our Tag & Track solution provide real-time visibility into tool availability, enabling .

Active RFID systems (otherwise known as active RTLS) use battery-powered sensor tags that connect to various access points throughout an area (like a building) and transfer data to the cloud. Active RFID is commonly used for real-time location tracking.

Active RFID for real-time tool monitoring. Companies that require real-time tool monitoring across their entire work-place often turn to active RFID. Active RFID provides strategic advantages for tool monitoring over passive RFID tags: Superior range of up to 300 feet.

RFID tool tracking systems can manage tools, including preventive maintenance, of all sizes, shapes, and materials – from small, metal surgical tools to large, metal and plastic power drills.

$25.38

active rfid tool tracking|rfid equipment tracking